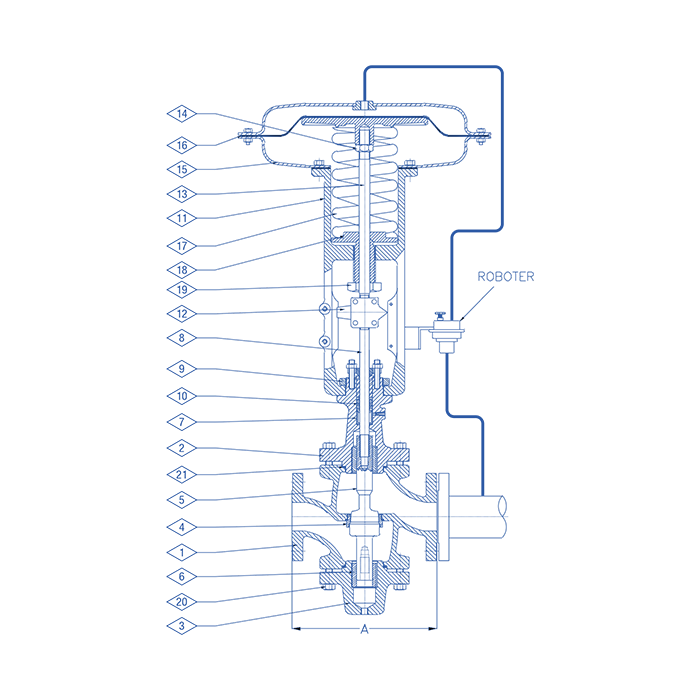

Pressure Reducing Valves

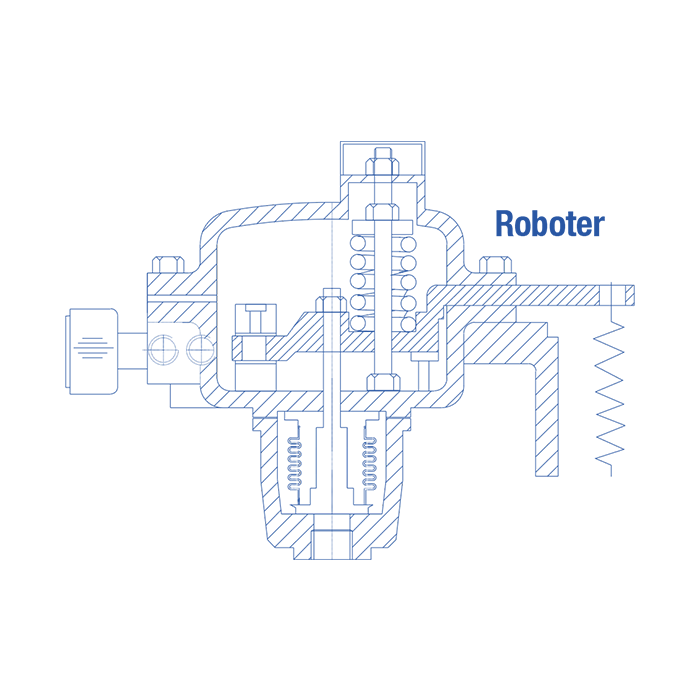

Roboter Operated - RCV-100 SERIES

Product description:

Globe Type, Single Seated, Top & Bottom Guided, Single Spring & Diaphragm Actuated, Roboter Operated Pressure Reducing Valve

Design:

- Roboter operated pressure reducing valve is high in demand where accurate down stream pressure control is required with high flow

- Top & Bottom guided design for high stability and accurate pressure control

Features:

- Top & Bottom guiding provides maximum support to the plug for it’s stability and eliminates the side thrust effect of pressure drop across the plug.

- This valves are designed to control fluid flow at high pressure

- This valves does not require external Instrumentation or Electrical signal

- Accurate down stream pressure control with high flow rate

- Turn down ratio for pressure is 20: 1

Application:

Bri-Con Roboter operated pressure reducing valve can be used for many Industrial application where reducing pressure of steam, gases and other fluids to be kept constant with high flow.

Accessories :

- Air Filter Regulator[ AFR ]

- Extended / Finned bonnet

- Bellows Seal

- Manual Override : Hand wheel

Ordering / Sizing Information:

- Fluid/State

- Flow Rate

- Inlet Pressure

- Outlet Pressure

- Operating Temperature

- End Connection

Technical Specifications

| Size Range | 25 mm to 150 mm |

| Pressure Rating | 150# to 600# / BS 10 Table H |

| Facing | Raise Face (R.F) , Flat Face (F.F) |

| Body M.O.C | Carbon Steel / Alloy Steel / Stainless Steel. |

| Trims | CF8 / 8M / SS 304 / 316 |

| Characteristics | Linear / Equal% / Quick Open |

| Outlet Pressure | up to 14 kg / cm2 |

| End Connection | Flange End / Butt Welded |

MATERIAL SPECIFICATIONS

| SR.NO. | Part Name | Material |

|---|---|---|

| 1 | Body | ASTM A216 GR. WCB / ASTM A217 GR WC6 / WC9 |

| 2 | Top Bonnet | ASTM A216 GR. WCB / ASTM A217 GR WC6 / WC9 |

| 3 | Bottom Bonnet | ASTM A216 GR. WCB / ASTM A217 GR WC6 / WC9 |

| 4 | Seat Ring | SS 304 / SS 316 / CF8 / 8M |

| 5 | Plug | SS 304 / SS 316 |

| 6 | Guide Bush | SS 410 |

| 7 | Spring (Bonnet) | SS 302 |

| 8 | Lower Stem | SS 304 / SS 316 |

| 9 | Lock Nut | Mild Steel |

| 10 | Gland Packing | Grafoil Ring |

| 11 | Yoke | S.G. IRON |

| 12 | Connector | ASTM A 216 GR. WCB |

| 13 | Upper Stem | SS 304 / SS 316 |

| 14 | Upper Stem Nut | SS 304 / SS 316 |

| 15 | Casing | Press Steel |

| 16 | Diaphragm | Buna-N Rubber with Nylon Rainforce |

| 17 | Actuator Spring | Carbon Steel |

| 18 | Spring Washer | Mild Steel |

| 19 | Adjusting Screw | Mild Steel |

| 20 | Fastners | ASTM A 193 GR. B7 / 2H |

| 21 | Gasket | Aramid Fiber (Non-Asbestos) |

Roboter Pressure Range

| Outlet Pressure Range | Bellows Type |

|---|---|

| 0.5 - 2.0 kg/cm2 | A |

| 2.0 - 8.0 kg/cm2 | B |

| 8.0 - 14 kg/cm2 | C |

Dimensions (mm) 150#

| SIZE | A ±2.0 |

|---|---|

| 25 | 184 |

| 40 | 222 |

| 50 | 254 |

| 65 | 276 |

| 80 | 298 |

| 100 | 352 |

| 150 | 451 |

Dimensions (mm) 300#

| SIZE | A ±2.0 |

|---|---|

| 25 | 196 |

| 40 | 234 |

| 50 | 266 |

| 65 | 292 |

| 80 | 317 |

| 100 | 368 |

| 150 | 473 |

Dimensions (mm) 600#

| SIZE | A ±2.0 |

|---|---|

| 25 | 209 |

| 40 | 250 |

| 50 | 285 |

| 65 | 311 |

| 80 | 336 |

| 100 | 393 |

| 150 | 508 |

Dimension & Weight

Coming Soon

Standards Followed

| ASME B16.34 | Pressure Temperature Rating |

| ANSI B16.5 | Flange Dimension |

| ASTM | Material Selection |

| ISA – S75.01 | Control Valve Sizing |

| ISA – S75.02 | Flow Capacity Test |

| ISA – S75.03/ISA – S75.15 | Face to Face Dimension |

| API 598 | Testing Standards |

| FCI 70.2 | Control Valve Leak Test |

Valve Cv Chart

| SIZE | Cv (GPM) | ||

|---|---|---|---|

| Equal% | Linear | Quick Open | |

| 25 mm | 13.9 | 16.8 | 16.3 |

| 40 mm | 30.4 | 30.2 | 30.9 |

| 50 mm | 55.2 | 55.4 | 58.7 |

| 65 mm | 77.0 | 76.0 | 82.8 |

| 80 mm | 102.0 | 118.0 | 120.0 |

| 100 mm | 170.0 | 166.0 | 155.0 |

| 150 mm | 372.0 | 377.0 | 369.0 |